#1 Brief development of LED for illumination

Generally Speaking, LED stands for Light-Emitting Diode.

1.1 DIP

The first LED designed for illumination was the dual in-line package (DIP) LED, which is also called a “straw hat LED.” Its light efficiency was relatively low at that time – only about 4-5 lumen per unit or 0.05-0.08 watt per unit, which is about 60-80 lumen per wattage.

1.2 SMD

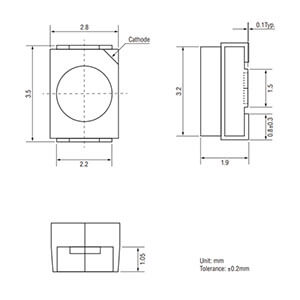

The Surface-Mounted Device (SMD) LED 3528 took the market by storm in 2008. One diode chip is encapsulated in a 2.8 mm x 3.5 mm rectangular-shaped SMD. SMD LED is also applied to the industry of digital signage.

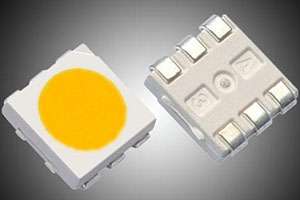

Later, the 5050SMD LED was developed. The SMD has three diode chips in a 5 x 5mm SMD. Since it has 3 chips, each also can be with a different color encapsulated(eg. Red, Green, Blue), it can be combined to create colorful lights.

The RGB (Red, Green, Blue) SMD LED and the 5050RGB SMD LED are widely used in colorful flexible LED strips.

1.3 COB

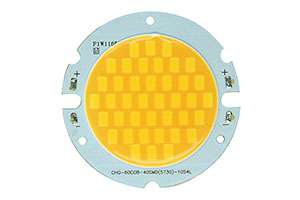

COB (Chip On Board) LED technology was first seen on the market in 2010, at the Canton Fair in Guangzhou. The COB can be either aluminum or ceramic; we will discuss this later.

First, let’s figure out: what is an SMD LED?

#2 What is an SMD LED?

SMD LED stands for Surface Mounted Device LED, which uses SMT technology to mount the LED chip on a PCB. The PCB is actually built in a rectangular-shaped, flat object, which is what we usually see as an SMD. If you peer into an SMD LED closely, you can see a tiny black point right in the center of the SMD; that is the LED chip.

The chip is covered with phosphor powder and looks yellow or orange. The orange one usually emits warm white light (2700-3500K) and the yellow one may emit daylight white (6000-6500K). A colorful 5050 RGB (refer to picture 4) does not have phosphor powder in it.

Above the phosphor power, a special type of optical silicon glue drips, eventually encapsulating the chip.

Its rear side has 2 metal points (anode and cathode) that are used to solder with the circuit in a lighting fixture. The 5050 has 6 metal points since it has 3 chips within.

SMD LED has different types: 2835, 3030, 3014, 5050, 5730, 5630; they are named according to their dimensions: length and width. For instance, the size of 2835 is 2.8 x 3.5mm. Please refer to the following table:

| SMD LED (module) | Dimension (mm x mm) | Power (Watt) |

| 3030 | 3.0 x 3.0 | 0.9 |

| 3528 | 3.5 x 2.8 | 0.06 |

| 5050 | 5.0 x 5.0 | 0.24 |

| 5630 | 5.6 x 3.0 | 0.5 |

Its rated power depends on the chip size; yes, it is the tiny black spot that is not always visible.

Reviewing the above information will make it easier to explain the COB.

Let’s move forward.

But, please note: the 3030 and the 5630, which have high power, come after the COB. This is important, as it will help you to understand why the COB has the commercial value so as to grab market share at that moment; namely, we had only the 3528 and 5050 before the advent of the COB.

#3 What is a COB LED?

COB LED stands for Chips On Board LED, and is a LED lighting source with a type of new encapsulation technology. Compared to the 3528: 1 chip on board, or 5050: 3 chips, a COB LED light source will have multiple chips (dozens or even hundreds) on the same PCB (Printed Circuit Board).

The COB has a PCB on its substrate; diode chips are arrayed in parallel or/and in series, depending on the circuit of the PCB. The substrate can be aluminum or ceramic. The ceramic type has a better thermal conductive performance that can guarantee a lower LED working temperature. Although the COB LED integrates many chips into one substrate, it only has 2 metal connection points: the anode and the cathode.

Since the COB mounts the chips directly to the substrate, which have a large cooling area, the COB has better thermal conductivity compared to the SMD. So, when we design a circuit on the substrate, we may consider shortening the chip’s distance to get the COB size as little as possible.

But why?

Why does the engineering tend to get a smaller size COB LED?

Let me explain:

In the SMD age, imagine you wanted to produce a 50 watt outdoor LED floodlight, while the 3528 only has a 0.06 watt. That means you will need about (50/0.06=833) 833 pieces 3528SMD on a floodlight altogether, and even each 3528SMD also needs space to ventilate and dissipate heat.

Apparently, normal LED floodlights will not have enough space for 833 pieces of 3528SMD.

That is impossible!

But in this situation, the COB LED comes in handy. Please refer to the following figures:

The 50W COB LED dimension is only 36 x 36 mm.

Only 36 x 36 mm will solve the problem, with 833 pieces of 3.5 x 2.8 mm – that’s darn fantastic.

The 50W COB LED dimension is only 36 x 36 mm.

Only 36 x 36 mm will solve the problem, with 833 pieces of 3.5 x 2.8 mm – that’s darn fantastic.

#4 The advantage of the COB LED

4.1 Better thermal conduction

Remember: we talked about the SMD, which has 2 metal points on its rear side (refer to figure.2). The heat dissipation process of the SMD would be: the heat produced by diode chips mainly go through the 2 electrodes, then go to the substrate (commonly, the aluminum), then go to the heatsink.

But for the COB, the process becomes simpler, because its chips are mounted directly to the substrate (aluminum or ceramic), the COB will have better thermal conductivity. Also, because of that, the chips’ distances are shortened and space is saved.

4.2 Lower the production failure rates:

Remember the floodlight story we talked about before? Manufacturing processes need to solder the electrode to the circuit. For the SMD, there would be 833 x 2 =1666 solder points; but for the COB, you only have 2 solder points to deal with – that will dramatically reduce the production failure rates. Furthermore, it saves labor time and you will pay less to workers.

#5 The disadvantage of the COB LED

The shape of the COB is predesigned to meet a special structure of lighting fixture – the array of the chips cannot be changed once they are encapsulated. But the SMD is more flexible – the array of its chips is decided according to the PCB circuit layout and it can be changed to meet different engineering solutions.

#6 Application of the COB LED light and the SMD LED

With the development of SMD LED technology, high-powered SMD, such as the 3030SMD, which has 0.9w rated power, came to the market now. So, making a high-powered floodlight with SMD became possible. Both the SMD and the COB have wide applications, but the COB shape is relatively customized to meet various fixtures.

any questions, please comments

Or you could share this useful information with your friends:)

References:

https://en.wikipedia.org/wiki/Surface-mount_technology

http://www.lextar.com/upload/media/PRODUCT/identfylogo/_20121022130715_18696.pdf

http://downloads.cdn.re-in.de/150000-174999/154355-da-01-en-LED_WARM_WEISS_SMD_900_MCD_TYP_120_GRAD.pdf